PVC tubing, the most popular type of vinyl tubing, is a particularly durable tubing that is resistant to many corrosive chemicals and abrasives; it is even occasionally used to transport highly volatile hydrocarbons. Because of its ability to endure pressure variations, vinyl tubing can be a great choice for conveying gasses, water, and a variety of other liquids. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

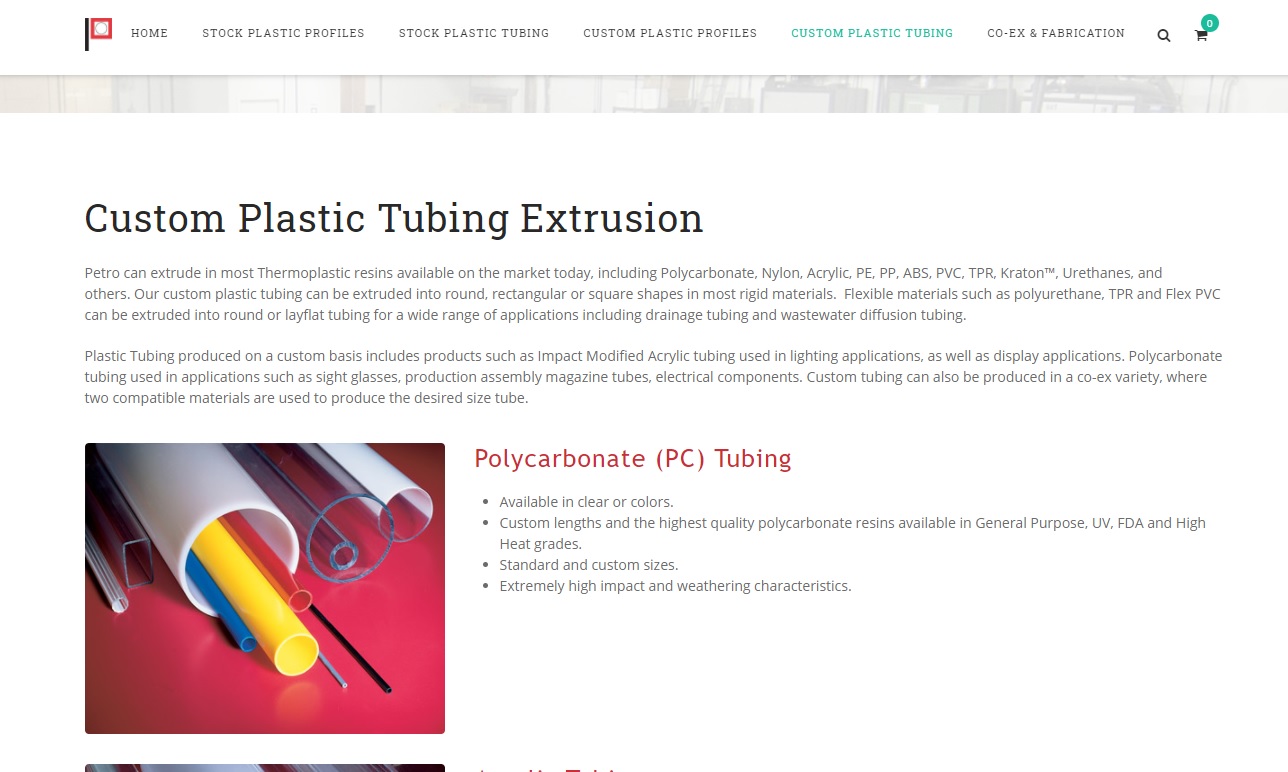

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

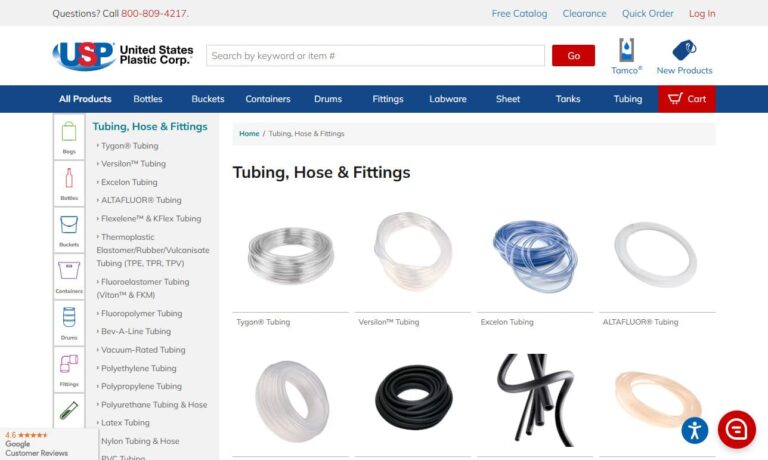

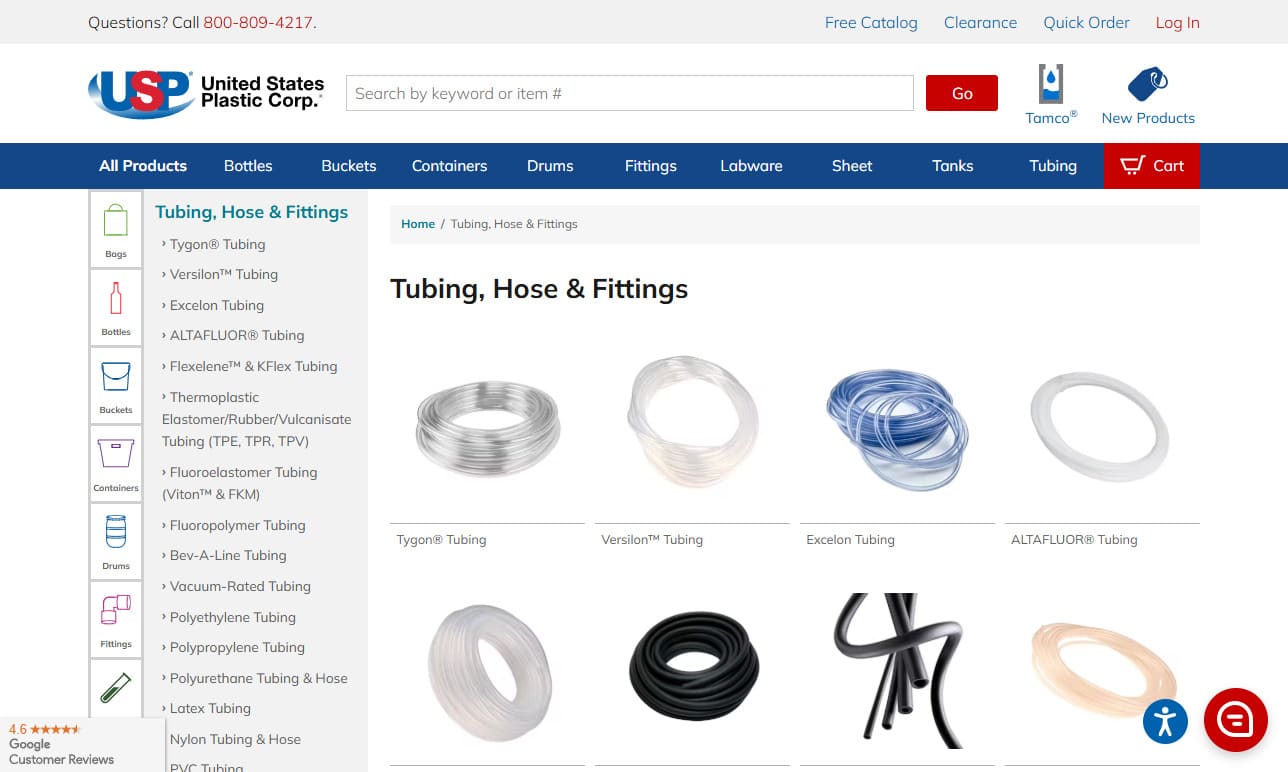

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Vinyl Tubing Manufacturers

How Vinyl Tubing is Made

Like most other plastic tubing items, vinyl tubing is typically made through extrusion. Thermoforming raw plastic materials is known as plastic extrusion (heat formed). The raw plastic material is collected in a hopper positioned above a conveyance channel to begin the plastic extrusion process.

The plastic material is forced toward a die by a lengthy screw within the conveyance channel. A die is a tool designed to form raw materials into useful products. A hole and a pin set in a metal plate are used in the extrusion of plastic tubes. The plastic material is driven through the hole in the die, which is heated by friction induced by the revolving screw and takes the shape of the die.

The plastic tubing emerges from the other side of the die, which is then allowed to cool and harden. The newly produced tubing is trimmed to length and ready for shipping or further processing at this point. Depending on the application, additional processing, such as coloring, may be required in vinyl tubing. Many tubes are also labeled so spectators can quickly determine what's within.

Types of Vinyl Tubing

The different types of vinyl tubing include:

PVC Tubing

PVC (polyvinyl chloride) is a versatile plastic with numerous physical properties, including good chemical and corrosion resistance and outstanding flow characteristics. It comes in various hardness levels, including wire/braid reinforced and rigid pipe. PVC comes in various formulas that are approved for use in various industries and applications. Some applications include potable water lines, food and beverage, chemicals, protective covers, and insulation sleeving.

EVA

EVA (Ethyl Vinyl Acetate) is a high-impact plastic with outstanding low-temperature qualities and good grease, oil, and weathering resistance. EVA tubing is a great alternative to vinyl tubing commonly used in surgical and pharmaceutical applications.

PVDF

PVDF is a melt-processable fluoropolymer with higher strength and less creep than other fluoropolymers. PVDF has strong chemical and wear resistance; however, it does not function well at high temperatures.

Applications and Advantages of Vinyl Tubing

The applications and advantages of vinyl tubing include:

Applications of Vinyl Tubing

- Vinyl may be developed to near transparency since it is nearly transparent in its raw condition, making it a great choice for applications requiring close monitoring or measurement of tube contents.

- Tubing applications in health care, for example, frequently necessitate convenient monitoring of intravenous treatment equipment.

- Vinyl's corrosion resistance, combined with its electrical non-conductivity, natural combustion resistance, and lack of toxicity, make it an excellent choice for transporting difficult goods.

- Brewing, pool operation, food processing, wastewater management, and various other applications employ vinyl tubing.

Advantages of Vinyl Tubing

- Plastic can withstand a lot of damage before breaking down. The wall thickness, resin blend, and amount of force that plastic tubing can withstand determine the plastic's durability and strength.

- All plastics, particularly polyolefins and PVC, are resistant to corrosion as determined by the type of polymer utilized. Polyethylene and polypropylene are polyolefins that come in various densities and molecular architectures to make design easier.

- PVC is a versatile material that may be used for a range of applications. Its sturdiness makes installation much easier in many circumstances, and it may be utilized in many locations, including ceilings, walls, and floors. However, the weight differential can be an issue.

Disadvantages of using Vinyl Tubing

- While PVC can be used to transport cold water and air all day, it has a maximum temperature rating. If temperatures are projected to be near or above the maximum range, this could limit some heating uses.

- Metal ductwork is extremely lightweight and thin, but PVC can weigh up to twice as much when constructed into equivalent structures, which may be restrictive in terms of construction and design.

Choosing the Correct Vinyl Tubing Company

To make sure you have the most productive outcome when purchasing vinyl tubing from a vinyl tubing company, it is important to compare at least 4 to 5 companies using our vinyl tubing directory. Each vinyl tubing company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each vinyl tubing company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple vinyl tubing companies with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services