Plastic compounds are used to make clear, translucent, opaque, or multi-colored thin wall plastic tubing. Thin wall plastic tubing is mostly utilized in packaging, packaging enhancement, and as an overwrap. It is extruded in various grades and compositions to suit regulatory requirements for custom applications. Read More…

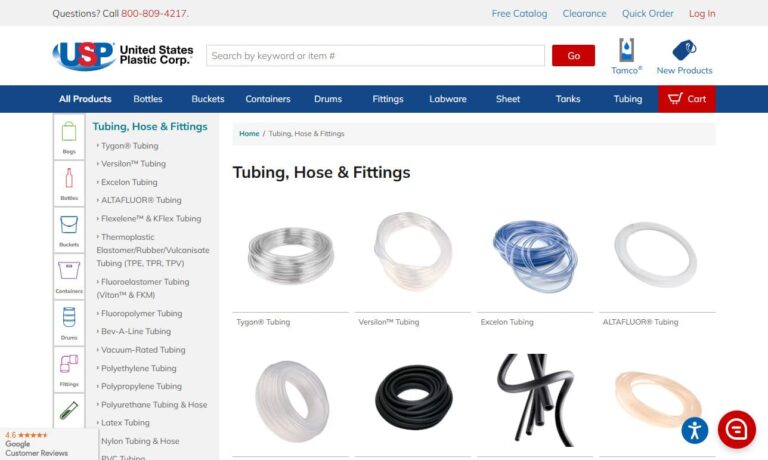

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

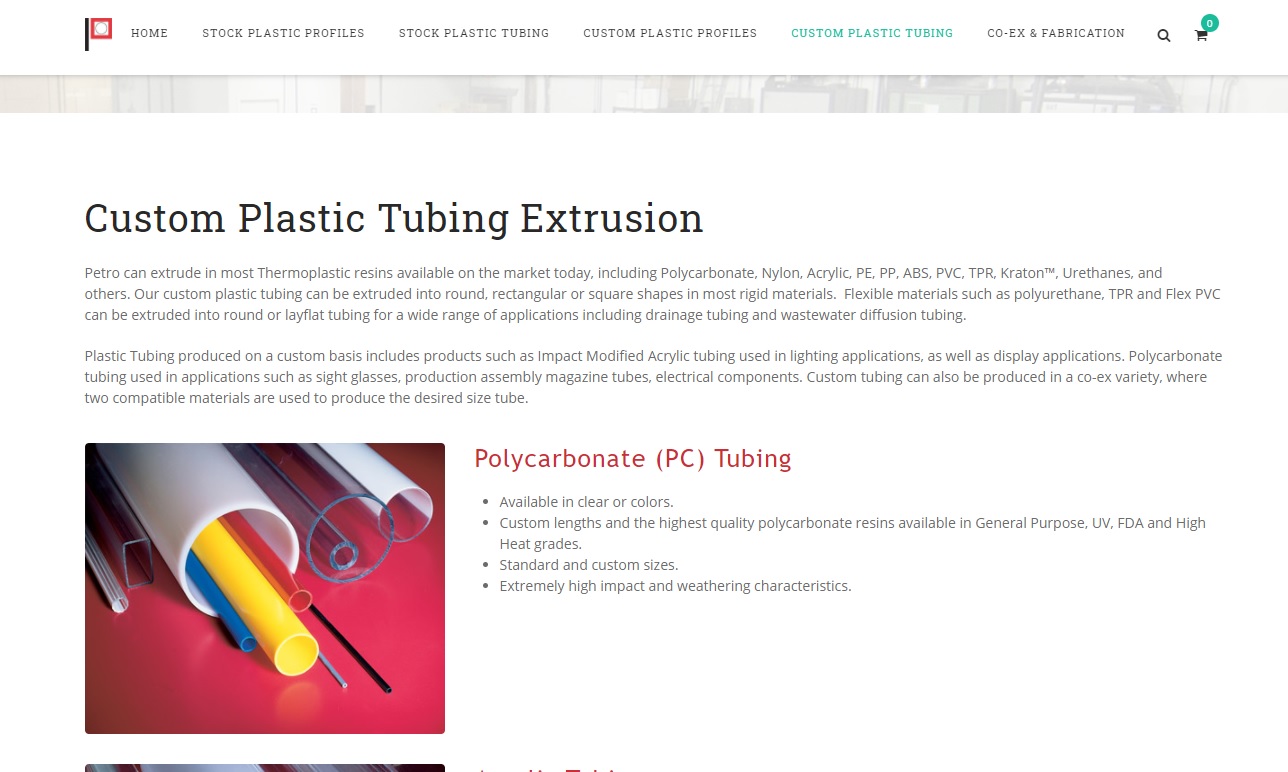

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

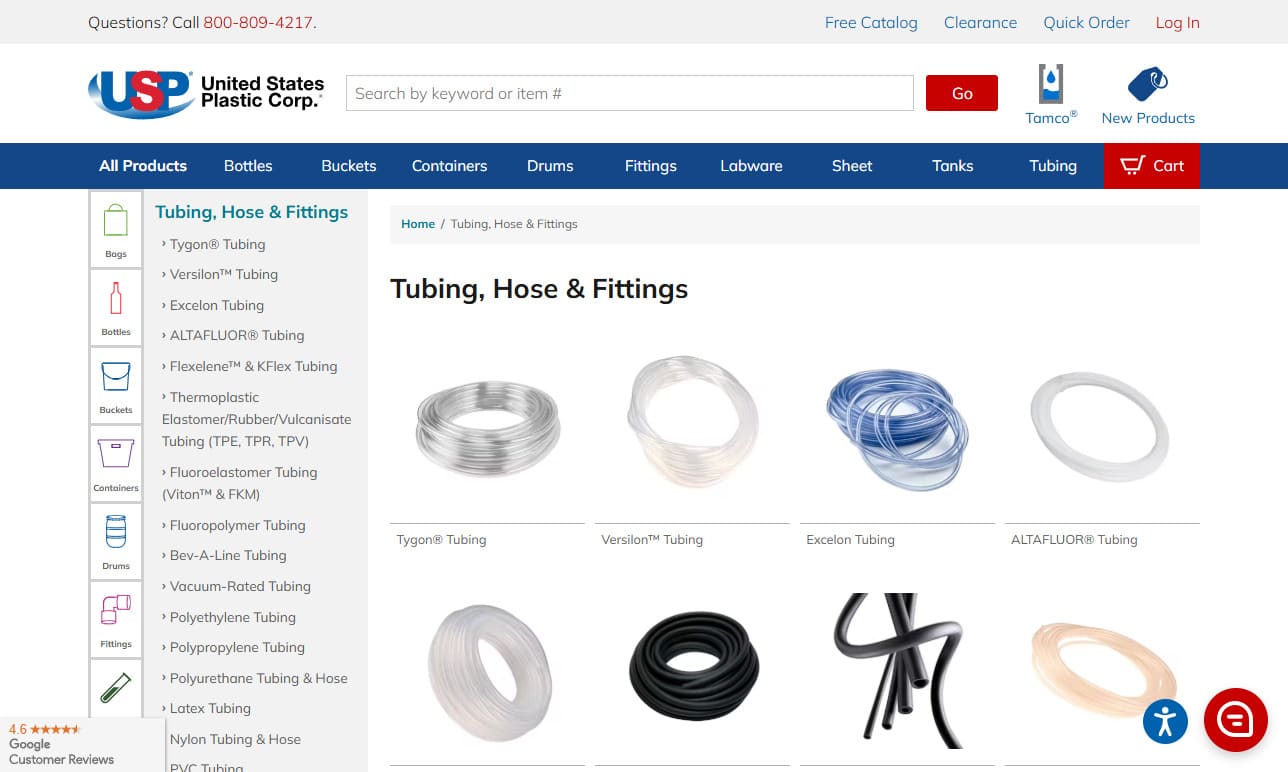

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Thin Wall Plastic Tubing Manufacturers

How Thin Wall Plastic Tubing is Made

Some of the processes involved in making thin wall plastic tubing are:

Tube Rolling Process

The first step is to cut the materials that have already been infused and roll them around in the mold. The mold is frequently wrapped in a sleeve during the second phase. This procedure is critical to eliminate the possibility of trapped air inside the mold sleeve. Heat is also useful in this process.

Finally, the mold is removed, revealing the desired hollow shape created throughout the process. To build a hollow mold of thin wall tubing, it's critical to roll the infused materials in a very tight wrapping. The goal is to integrate this method into a tight bonding to generate the desired output.

Tube rolling guarantees that the thin-walled tubes are extremely accurate. Because this is a unique and extra-precise procedure, it can be quite elaborate and costly.

Extrusion Process

Tube extrusion, on the other hand, is a considerably more common and straightforward technique than tube rolling. The spherical items are pounded strongly during this operation to incorporate them into the die. The die is already hollow and in the shape that the manufacturer prefers. The material injected into the die takes on the shape of the die. The role of high temperature in this process is critical.

The material cannot be inserted into the die without high temperatures; thus, the use of high temperatures is critical. Furthermore, both procedures result in the extrusion of the material. The extruded material is the result of either indirect or direct extrusion. When direct extrusion occurs, the die remains stationary in one location.

On the other hand, the material is hammered into the hollow die's opening. The interior material is extracted from the die's second aperture in indirect extrusion. The remaining material takes on a hollow shape. This allows for the creation of thin-walled tubing that can be stretched into the desired shape and length. There are numerous phases in tubing manufacturing, so there are numerous factors to consider.

Grades of Thin Wall Plastic Tubing

Thin wall plastic tubing is available in various grades, including FDA standard and flame retardant. It can also potentially be built to satisfy UL standards. In addition, UV stabilizers may be included in tubing for outdoor use. Polyethylene Terephthalate Glycol (PETG), Polyethylene Terephthalate Polyester (PET Polyester), High Impact Polystyrene, and Polyvinyl Chloride are some plastics used to make tubing. Finally, the tubing can be either hard or flexible.

Applications and Advantages of Thin Wall Plastic Tubing

The applications and advantages of thin wall plastic tubing include:

Applications of Thin Wall Plastic Tubing

Thin wall plastic tubing is used in various applications and sectors, including packaging for crafts, toys, food, and sweets, medical and pharmaceutical, electronic, cosmetic, and personal hygiene.

This tubing should only be used to package lightweight or non-fragile items like novelty items, toys, posters, confectionery products, baked goods, houseware, and anything else that requires low-cost, attractive packaging. Even when packaging sales items, thin wall plastic tubing provides appropriate protection for retail items while remaining reasonably priced.

It can also be made to endure severe temperatures, which is critical for a product's integrity and safety. Thin wall plastic tubing can be used for catheter tubing, catheter lines, and other medical tubing outside the retail industry.

Advantages of Thin Wall Plastic Tubing

- Machines can employ fewer fittings and welded contraptions because of the flexibility of these tubes; this is why the manufacturing costs are so low. Because there are fewer welded spots, the operation becomes considerably more crisp and clean. It also lowers the occurrence of leaks. Because of the flexible tube bending, the amount of chemical and liquid trapped in welded sites is reduced.

- Thin wall plastic tubing is an excellent technique for carrying various liquids and gasses because the already-thin walls enable safe travel. Steel is an excellent choice for corrosive products and materials because of this.

- Although thin wall stainless steel tubes are created over a series of steps, they retain their qualities thanks to the employment of accurate CNC benders. This will be quite useful in future applications. Heat loss is minimal during the operation, which is an important consideration for industrial activities. The tube bend is extremely precise, ranging from 0.005 to 0.010 inches (0.127 to 0.254 mm).

Choosing the Proper Thin Wall Plastic Tubing Supplier

To make sure you have the most beneficial outcome when purchasing thin wall plastic tubing from a thin wall plastic tubing supplier, it is important to compare at least 5 companies using our list of thin wall plastic tubing suppliers. Each thin wall plastic tubing supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each thin wall plastic tubing company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple thin wall plastic tubing companies with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services