Tubing is an extruded, non-reinforced cylinder of any size. Rigid plastic tubing is a form of plastic tubing that can be utilized in applications that need stiff and unbending tubing. Frequently, the tube must meet FDA, NSF, or UL specifications. Medical, plumbing, mining, gas transportation, and beverage industries use rigid plastic tubing. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

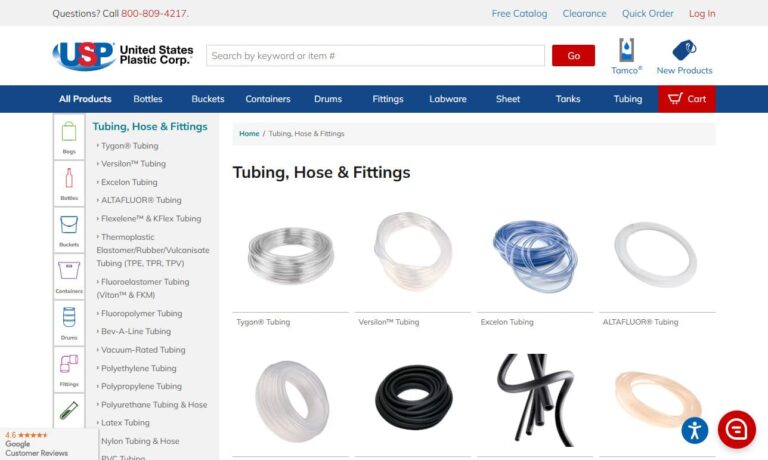

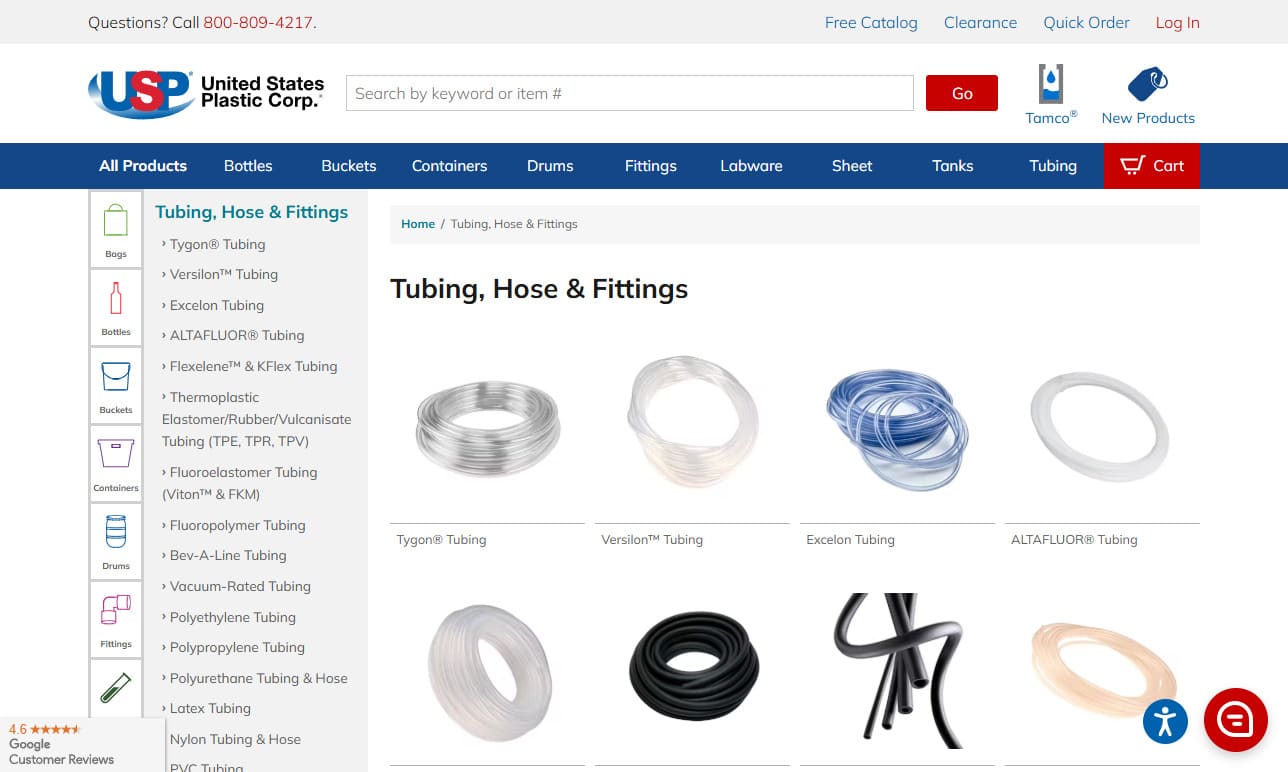

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Rigid Plastic Tubing Manufacturers

How Rigid Plastic is Made

ABS, CABS, PVDF, PET polyester, polypropylene, HO, polypropylene, CO, polyvinyl, polystyrene crystal, acrylic, and stiff polyvinyl chloride are some of the materials used to make rigid plastic tubing.

Thermoplastics are among these materials. A thermoplastic is a plastic (polymer) that becomes moldable or pliable above a certain temperature before solidifying when cooled. This means the plastic can be melted and remolded without damaging its molecular structure. This aids in molding and extruding hard plastic tubing into a variety of shapes, including round, oval, triangular, rectangular, square, and bespoke (custom).

Semi-Rigid Plastic Tubing

This type of plastic tubing is durable, lightweight, and resistant to abrasion, crushing, and cracking. Semi-rigid plastic tubing is ideal for fluid transfer because it is resistant to flexural fatigue, tube vibration, and movement.

Furthermore, this type of plastic tubing has a large bend radius to reduce kinking and absorbs minimal moisture to prevent swelling from water. Round, oval, triangular, rectangular, and square are extruded shapes for rigid and semi-rigid plastic tubes.

Benefits of Using Rigid Tubing

- Hard plastic tubing is light, strong, and resistant to various internal and external damages. It's also corrosion and pitting resistant. Its lightweight saves money on transportation, handling, and installation, and it can also sustain knocking damage, which is a concern with traditional cast-iron pipes. Plastic pipe lengths can be chopped into larger portions to reduce the number of joints.

- Plastic is resistant to corrosion, fungus, and mold, making it ideal for delivering water in a more sanitary manner, resulting in improved health outcomes.

- Another advantage of strong plastic tubes has been their ability to remain flexible enough to conform to earth movements, a desirable trait in earthquake-prone areas.

- Plastic is a chemically inert and stable substance that can withstand various chemicals. Compared to cast-iron, GI, and other typical plumbing pipes, it is also incredibly cost-effective. Due to the flat surface, it has a lower barrier to flow; as a result, liquid transfer across long distances is more efficient. Because plastic pipes are resistant to many things, there is less loss due to wastage, resulting in significant cost savings. Plastic pipe installation is relatively simple and does not require any particular skills.

Applications of Rigid Tubing

Plastic tubing has a hollow center and is used to transport liquids, air, or solids. It comes in a round, rectangular, or square shape. Crimp-resistant plastic tubing comes in a range of bend radii (flexibility), chemical resistance, wall thickness, durometer hardness, and temperature and pressure-handling capabilities.

In a fluid handling system, barbed fittings are used to connect tubing or deflect flow. Other plastic tubing has a wide range of industrial applications. Tubing for beverages, cores, and dip tubes are some of the most popular applications for rigid and semi-rigid plastic tubing.

Plastic tubing can be transparent (clear), translucent (semi-clear), or opaque (solid) in a variety of colors, and the color of the tubing can indicate its suitability for certain uses. Each color option has its own set of benefits. Clear tubing, for example, is essential for fluid handling procedures where the flow must be watched.

Solid color tubes are useful in applications where several tubes need to be distinguished as separate flow lines or cables by using different colors. Partially transparent tubing allows light to pass through, permitting fluid to be monitored while being largely hidden from the outer world, which could be useful for regulation.

Finally, multi-colored tubing can be used for decoration or signaling. It can be high gloss or matte, and it can accommodate a variety of wall thickness needs. Rigid plastic tubing can be drilled, cut, machined, stamped, bent, and joined to other tubes.

Examples of rigid plastic tubing applications include beverage tubing, cores, dip tubes, feeder tubes, filtration tubes, irrigation tubes, medical tubes, packaging tubes, sample tubes, shipping tubes, and rigid plastic for structural applications.

Choosing the Right Rigid Plastic Tubing Manufacturer

To make sure you have the most beneficial outcome when purchasing rigid plastic tubing from a rigid plastic tubing manufacturer, it is important to compare at least 4 to 5 companies using our list of rigid plastic tubing manufacturers. Each rigid plastic tubing manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rigid plastic tubing company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rigid plastic tubing companies with the same message.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services