Polypropylene is a thermoplastic polymer. Its many uses are packaging and labeling, textiles, stationery, laboratory equipment, plastic parts, reusable containers, and automotive equipment. Because it is lightweight but strong, resilient but flexible, and affordable but fatigue-resistant, polypropylene is quite popular. These characteristics also apply to polypropylene tubing, an extruded, non-reinforced cylinder of any shape made of polypropylene. Read More…

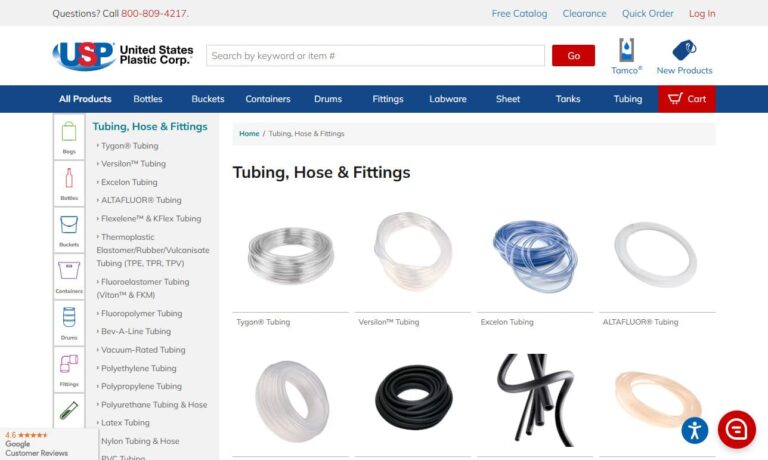

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

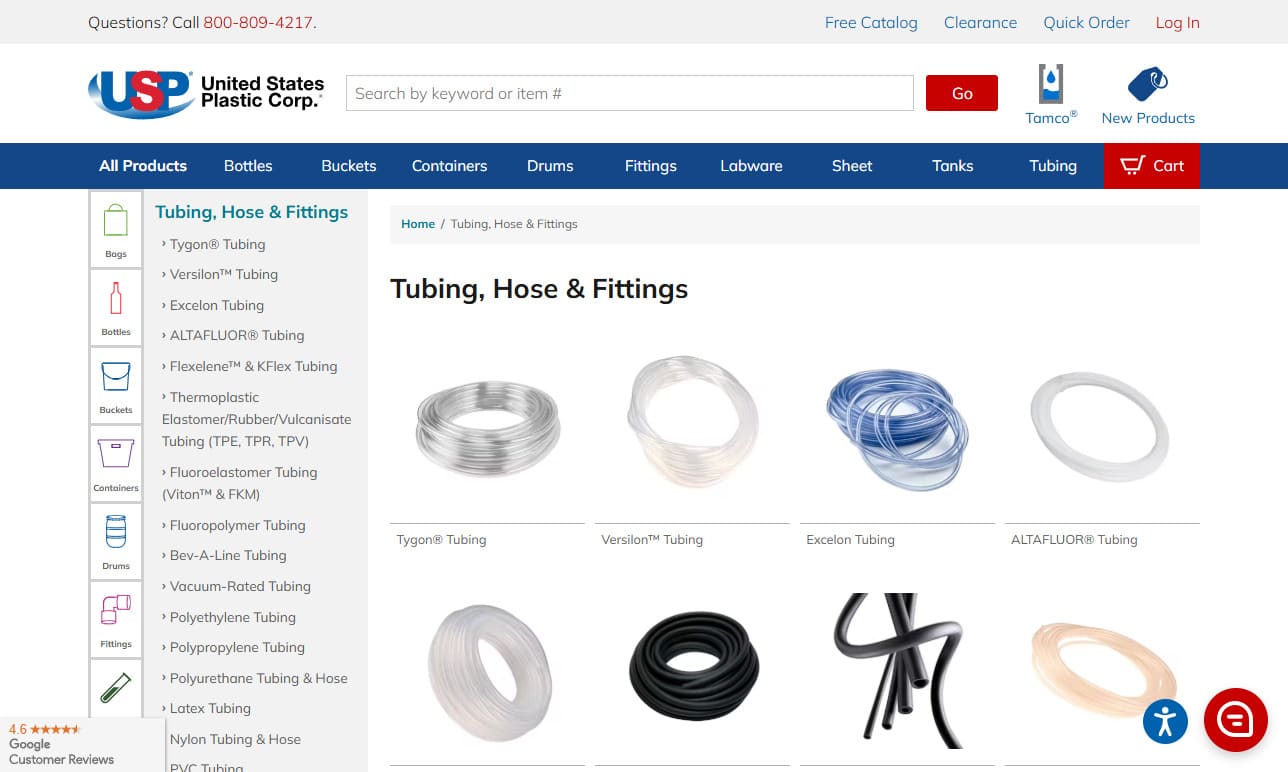

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Polypropylene Tubing Manufacturers

Polypropylene Tubing Advantages

Polypropylene tubing has the qualities listed above and is chemically and thermally resistant. Compared to polyethylene tubing, polypropylene tubing is stiffer and heat-tolerant, having a melting point that varies but often hovers around 250 °F. In addition, this tube has lots of other excellent qualities. For instance, it has excellent electrical and dimensional stability, good surface hardness, and ease of coloring. It can also float.

Additionally, it is weldable and can be applied in non-fluid transfer applications after being welded. Finally, fluoropolymer tubing can be replaced by polypropylene tubing at a lower cost due to its physical characteristics and low manufacturing cost.

Drawbacks of Polypropylene Tubing

The drawbacks of polypropylene include its susceptibility to heat, chemicals, and other particular elements. More specifically, its drawbacks are:

- UV-related degradation prone

- aromatic and chlorinated solvent sensitivity

- extremely flammable

- sensitive to oxidation

- Due to its low bonding abilities, it is challenging to paint.

Polypropylene Tubing Design

Customized features and accessories for tubing can be ordered. It may be transparent or come in solid, numerous, or translucent hues. Additionally, it is capable of a wide range of lengths and inside-and-outside diameters.

Uses for Polypropylene Tubing

Polypropylene tubing is a great investment for laboratory and industrial use, including injection molding and hot fill applications. In applications involving the processing of food and beverages, it is also appropriate for use in transporting hot liquids and gasses. Automotives, compressed air, dispensing equipment, electronic equipment, environmental monitoring, home furnishings and appliances, instrumentation, personal care items, pharmaceutical processing, potable water systems, refrigeration, and semiconductor manufacturing are some additional applications where polypropylene tubing may be useful.

Polypropylene tubing is suitable for structural systems due to its high crystallinity. It may be utilized, for instance, as a liner in metal piping systems or as a support structure for small fluid systems. Generally, it should be employed in any industrial process that requires exceptionally high resistance to acids and alkalis.

Properties of Polypropylene

Combinational Quality

Polypropylene provides corrosion resistance, anti-rust ability, portability, low density, high-temperature resistance, aging resistance, relative service life shorter than polyethylene (PE), good surface finish, good thermal stability, low melting rate, excellent surface smoothness, good recognition for food grade, and low cost.

Stability of Chemicals

The polymer polypropylene (PP) has excellent chemical stability. Except for concentrated sulfuric and nitric acids, PP is generally stable when exposed to other chemical reagents. However, low molecular weight aromatic, chlorinated, and aliphatic hydrocarbons can soften and swell it. In the meantime, as crystallinity increases, it becomes more chemically stable. Therefore, PP can be used to make a variety of chemical pipes and fittings with good anti-corrosion properties.

Thermodynamics

PP can withstand heat well. Sterilization of its product is possible at temperatures higher than 100 °C. Without outside effort, it can maintain its shape at 150 °C. However, its embrittle temperature is -35 °C, meaning that when the temperature is below -35 °C, PP will become embrittled. Therefore, its resilience to cold is lower than PEs.

Weather Resistance

UV light can cause PP to break down. Additionally, adding zinc oxide, dilauryl thiodipropionate, carbon black, or another similar opal filler might increase the PP’s ability to resist aging.

How Polypropylene is Produced

Propylene gas is polymerized using a catalyst system, most frequently a Ziegler-Natta or metallocene catalyst, to create polypropylene. Then, the polymerization conditions—including temperature, pressure, and reactant concentrations—are chosen according to the desired polymer grade. In either a gas-phase or a liquid-phase process, a variety of manufacturing techniques are possible:

Gas-Phase Reaction: The gas-phase reaction takes place in a fluidized bed reactor at a pressure of 1–20 atm and a temperature of 70–100°C. Over its catalytic bed are carried hydrogen and propane. After transforming into polypropylene as a fine powder, propane and hydrogen are removed from the polymer using cyclone separators. This fine powder is pelletized at the end and is then prepared for use. In general, gas-phase polymerization efficiency can be increased by removing gaseous and aqueous effluents using high-activity catalysts.

Spheripol Process: This polymerization method creates polypropylene from propene, ethylene, and hydrogen. The catalyst and monomer units are suspended in an inert solvent, such as light hydrocarbons, where the reaction takes place. Then, the slurry of monomer and catalyst is pumped into one or two vertically stirred gas phase reactors, where polymerization occurs. The unreacted monomer is recycled back into the stirred gas reactor when the polymerization process is complete. The combination of monomers and polymer powder is discharged from the reactors through dip tubes. The polymer is then kept for future application.

Choosing the Right Polypropylene Tubing Manufacturer

To ensure you have the most positive outcome when purchasing polypropylene tubing from a polypropylene tubing manufacturer, it is important to compare several companies using our directory of polypropylene tubing manufacturers. Each polypropylene tubing manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the manufacturer for more information or request a quote. Review each polypropylene tubing business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple polypropylene tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services