Plastic tubes are shapes created through the extrusion of plastic. Extrusion is the process through which melted raw plastic material is forced through a die to create a shape. The final shape is created when the extruded plastic solidifies after cooling. Extrusion is used to create both plastic tubes and rods. However, they are created differently since plastic tubes are hollow while plastic rods are solid. Read More…

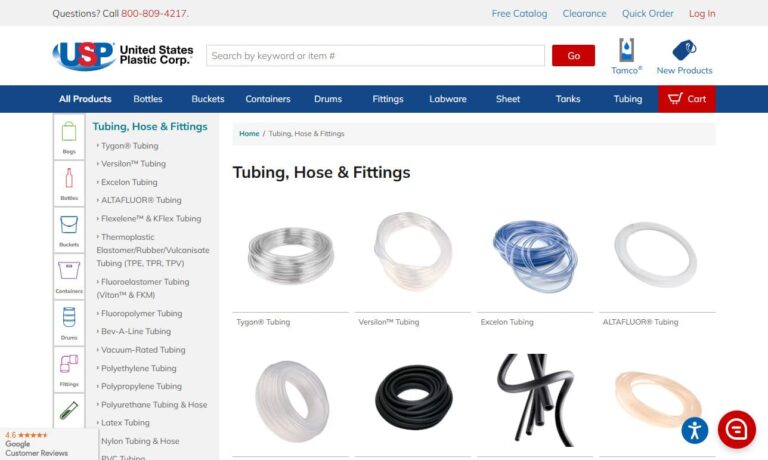

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

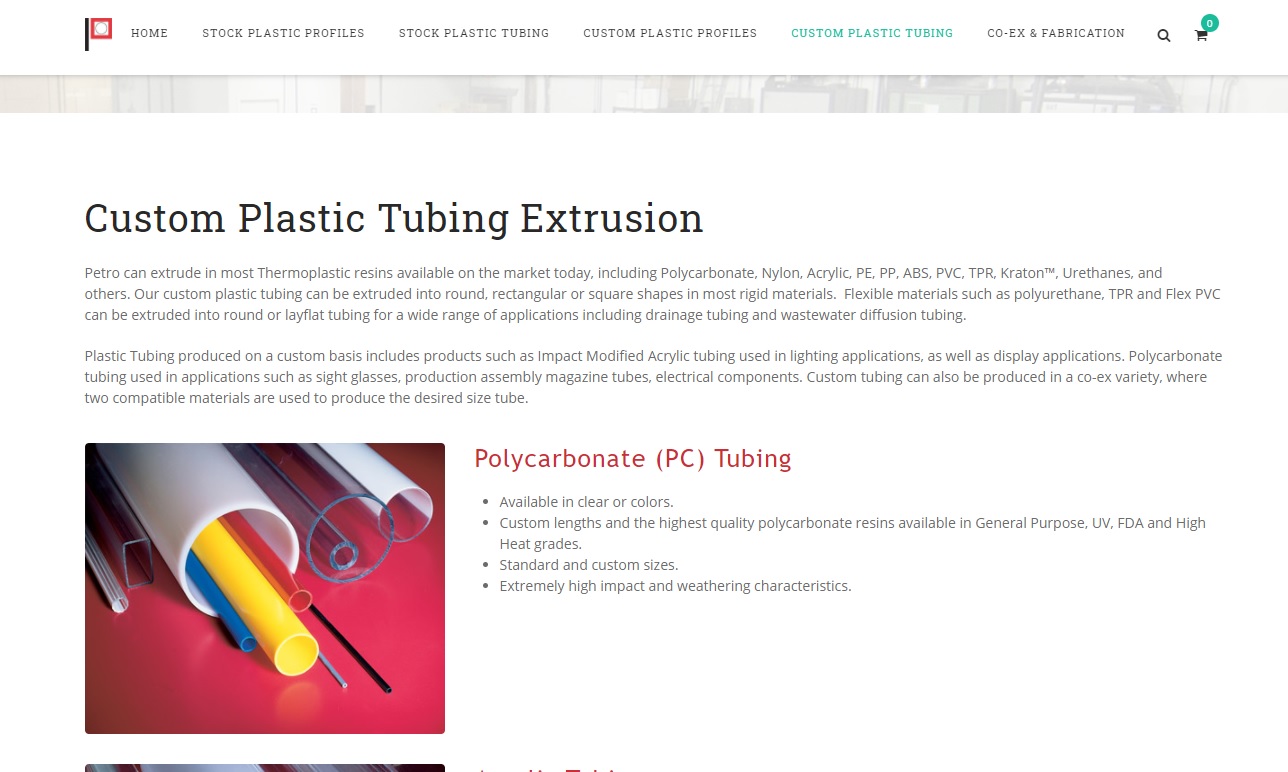

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

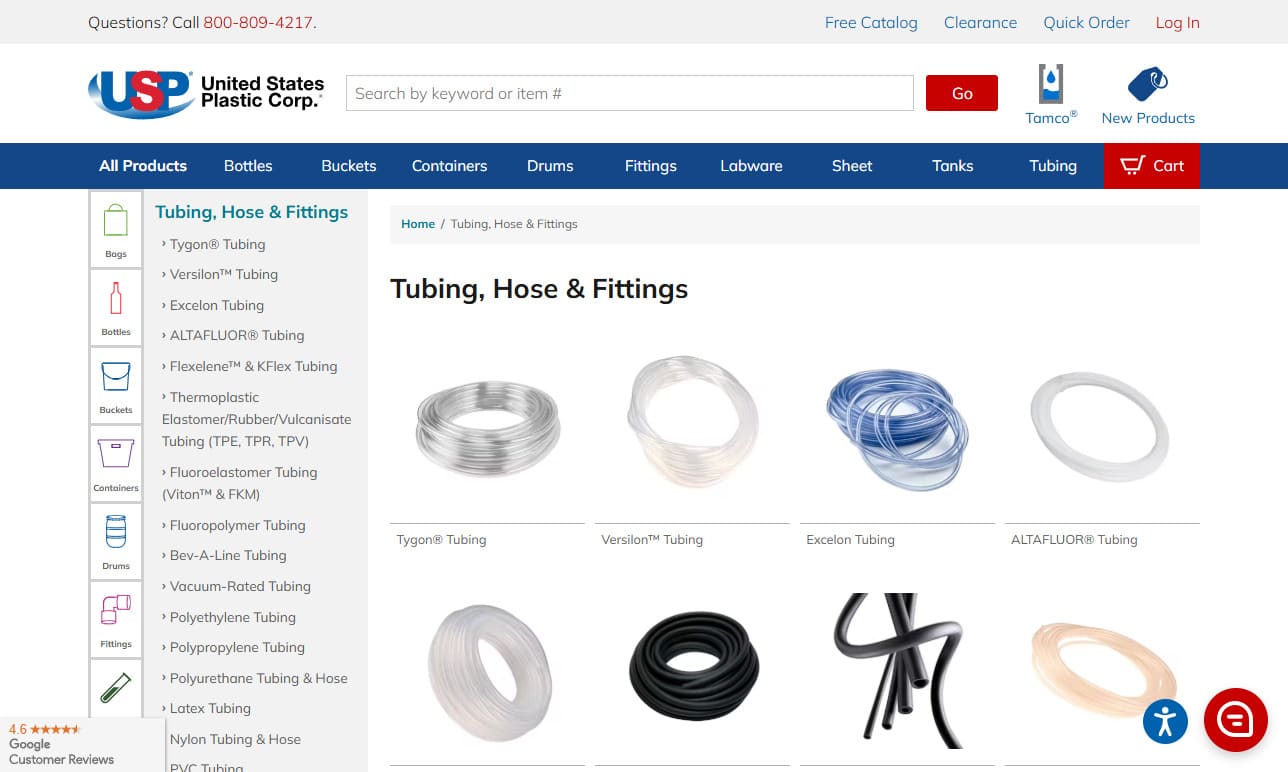

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Plastic Tube Manufacturers

Plastic Tube Variations

There are numerous varieties of plastic tubes, and each is favored in a particular application because of the special properties of the plastic. Due to their optical clarity, impact resilience, and availability in various colors, acrylic tubes are frequently utilized for lighting applications. Due to their great abrasion resistance and self-lubricating qualities, UHMW tubes are frequently used for guide rails, wear plates, and rollers. Due to their exceptional flame & smoke properties and high chemical resistance over a wide range of temperatures, Vespel® tubes are employed in aviation and aerospace applications.

Types of Plastics Used as Tubes

Different types of plastic materials have different strengths, reactivity, and transparency characteristics, which alter the plastic tubes that can be made. For instance, acrylic tubing is frequently almost transparent, reasonably robust, and affordable. On the other hand, despite having the ability to be manufactured to be nearly clear, polyvinyl carbonate (PVC) is frequently opaque and is hence frequently utilized in plumbing applications. Tubing is made of a wide range of different plastics.

A few examples include nylon, high- and low density polyethylene (HDPE and LDPE), polypropylene, polystyrene, PET, ABS, and polyurethane. Healthcare, heating and cooling, municipalities, labs, home and garden product makers, pool supply firms, petrochemical processing facilities, agriculture, and other sectors are major consumers of plastic tubing products. Due to its adaptability, simplicity in manufacture, and relative affordability when compared to other materials, plastic tubing is utilized extensively. For instance, glass tubing is more expensive, heavier, and prone to breakage.

The type of plastic material is of utmost importance when choosing plastic tubing. This factor is crucial because most of the tubing's physical characteristics will change depending on the type of plastic used.

- EVA (Ethyl Vinyl Acetate) has outstanding low-temperature qualities, strong impact strength, and exceptional resistance to weathering. As a result, EVA tubing is a great replacement for some vinyl types used in surgical and pharmaceutical applications.

- A melt-processable fluoropolymer with greater strength and less creep than other fluoropolymer kinds is polyvinylidene fluoride (PVDF). Although PVDF has strong chemical resistance and good wear resistance, it struggles at high temperatures.

- Due to its high inertness, polyethylene (PE), a lightweight plastic, is frequently used in food and beverage, laboratory, and chemical processing applications. It can handle many applications and is noticeably less expensive than most other plastics.

- Because of its superior elastic memory, nylon can sustain repetitive flexing for an extended period without wearing out or damaging the tube. Additionally, it has a high impact resistance that endures temperatures below zero and low moisture absorption that reduces size and dimensional instability.

Applications of Plastic Tubes

Health Care Products

It is not surprising that hospitals choose plastic tubes as a reliable and user-friendly solution for medical supplies and equipment, given how swiftly the medical industry is evolving. Because it resists dents and permeation, plastic tubing is a perfect option for supplies like:

- Catheters and needles

- IVs

- Drainage apparatus

- Nutrition tubes

Instruments used to diagnose patients, and transport fluids also contain plastic tubes.

Irrigation Equipment

Both irrigation equipment and rain are necessary for a plant's growth. Underground water pipes, sprinkler systems, or domestic hoses are all examples of irrigation equipment. And for each of them, plastic tubing is frequently the preferred option.

Agricultural Applications

To keep their crops healthy and thriving, farms employ subterranean pipes to keep a water supply available. Plastic also gives the flexibility and durability that the other materials frequently lack, even though steel and brass are popular choices. Farmers who use plastic tubing may drive heavy machinery over the subterranean tubing without worrying about the pipes breaking since the plastic's elasticity allows the pipes to bend rather than break.

Residential Use

A sprinkler system or hose used to water the lawn or garden is built of plastic tubes and is intended to withstand common household damages like bugs.

Vehicle Fluid Transmission

The smooth operation of various automobiles depends on a range of fluids. And the liquids are transported by plastic tubes to their intended locations. Plastic tubing is made to survive the heat of an automobile engine, even on the hottest summer days. It can also tolerate temperature damage and corrosion. Additionally, the tubing resists chemical deterioration from substances like gasoline and transmission fluid. It is a great option for the automobile industry because of these characteristics.

Shipping and Packaging

Producers, retailers, and shippers use plastic tubes to package and transport a wide range of goods because of their strength and adaptability. Plastic tubes can be created to fit large and tiny objects, as well as those with odd shapes. Distributors can be confident in the products' security during transit and while they wait to be purchased because of plastic tubes’ endurance. It is noticed that plastic is frequently used in shipping tubes to protect goods from impact, wetness, and particle damage.

Choosing the Right Plastic Tube Supplier

To ensure you have the most beneficial outcome when purchasing plastic tubes from a plastic tube supplier, it is important to compare several companies using our directory of plastic tube suppliers. Each plastic tube supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic tube business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic tube companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services