Square plastic tubing refers to devices that offer a hollow path for moving gases, liquids, or granular or free-flowing materials. Plastic tubing is a practical solution for many industries and applications. Due to its square and non-cylindrical shape, it is easily distinguished from other tubes. Square tubing is easy to anchor, making it ideal for stationary devices. Read More…

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

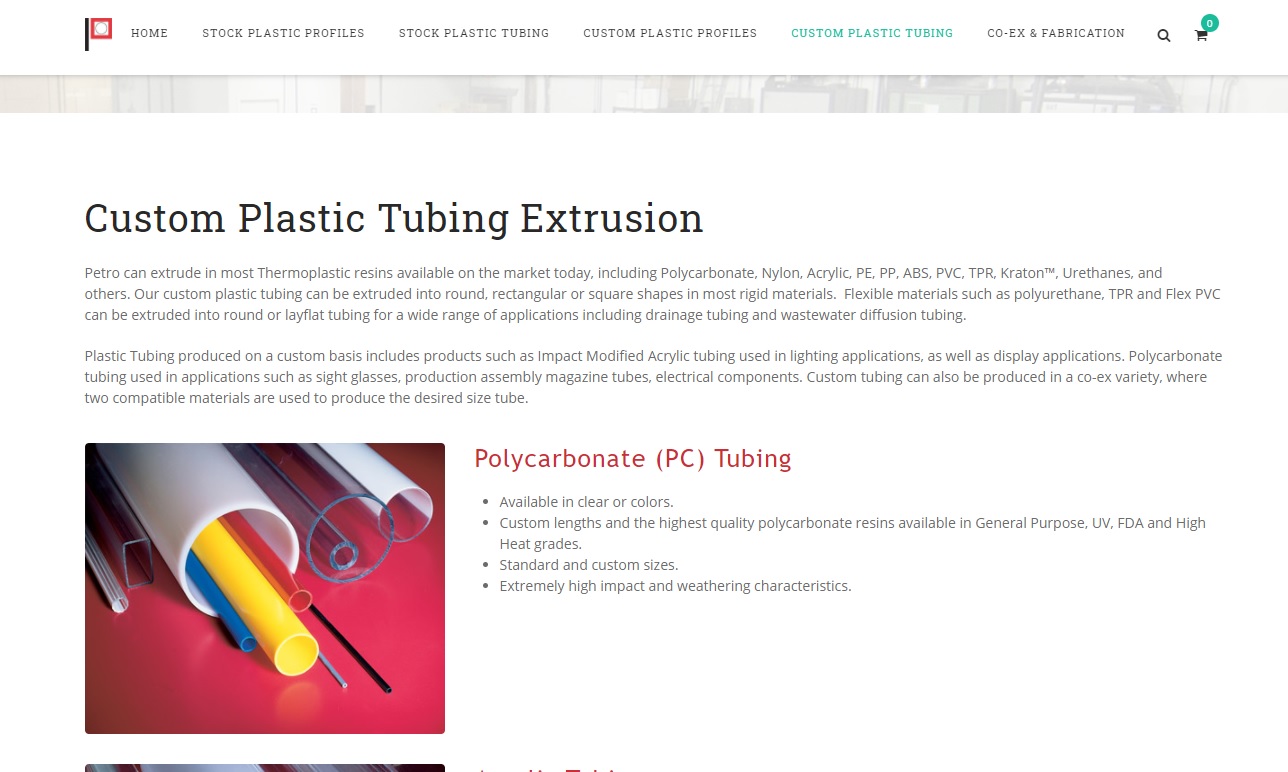

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Square Plastic Tubing Manufacturers

How Square Plastic Tubing is Made

The requested pipe dimensions must first prepare the tube tooling to create a PVC box hollow square tubing. Manufacturers can create square tubing with plastic extrusion and cell casting processes. When cell casting is used, the finished item is removed from the mold in its solidified form.

The plastic extrusion process is noticeably more efficient than cell casting. Plastic extrusion is a thermoforming technique used to mold the plastic into the required shape. The first phase in the plastic extrusion process is collecting raw plastic material, sometimes referred to as stock. The next step is to put the stock into a hopper hanging above a conveyance channel. The conveying channel has a die, heating components, and a big shearing screw.

A die and mold tools are used to form the material. The moving screw creates heat and friction, releasing the stock into the channel. The stock is heated into a molten form. The desired shape is created when the molten stock is pressed through the die. The tube is removed from the die and cooled. After lengthening, the tube is prepared for either additional processing or export.

Types of Square Plastic

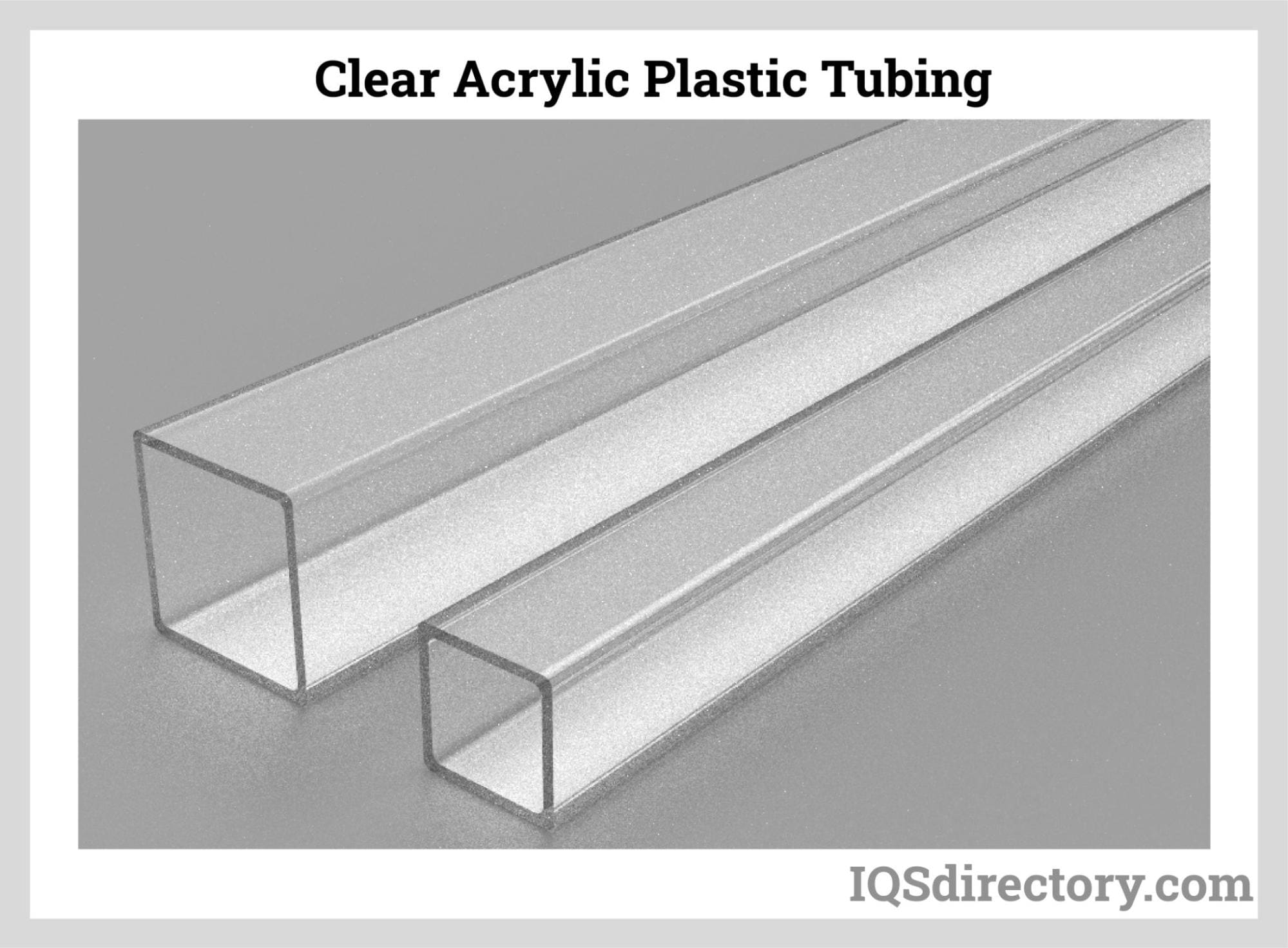

Clear Acrylic Plastic Square Tubing

The acrylic extruded clear square tube has a smooth interior and exterior surface. It is often used in lighting systems and display applications.

Two-Colour Coextrusion Plastic Square Tubing

Some plastic square tubes and pipes can be made with two colors during coextrusion. Diameters of square and rectangular plastic tubes can have mechanical stress resistance, high heat stability, and smooth surfaces.

Square Plastic Tubing in the Automotive Industry

In the automotive sector, researchers are designing newer, lightweight automobile models with plastic tubes. Plastic tubing is robust and flexible enough to resist deterioration. The potential is infinite with the growth of 3-D printing. Making custom plastic tubing with 3-D printing will enable more effective space utilization.

Applications of Square Plastic Tubing

Whatever its shape, plastic tubing is used in a variety of sectors and is made from different types of plastic. These materials include nylon, polypropylene, PET, polyurethane, high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polyurethane. These plastic substances differ in transparency, tensile strength, and reactivity. For instance, to readily monitor fluid flow, a healthcare facility could use square plastic tubing in its laboratory equipment. Plastic tubing is the best material for transmitting gases and liquids because it is resistant to corrosion and has excellent levels of sterility and cleanliness.

Additionally, plastic tubing is employed in devices like plastic hearts and scoping tools, which can enhance and even save patients' lives during various surgical procedures. Tubing made of PVC and HDPE are options renowned for their strength and impact resistance. PVC is hazardous, though, and several sectors, including the medical sector, are becoming more worried about the dangers that PVC can provide. As a result, stronger regulations have been put in place, and ongoing research is being done to create fresher, more creative substitutes for different kinds of plastic.

What to Take into Account When Selecting Square Plastic Tubing

Square plastic tubing may be preferred by some people purely for aesthetic reasons or because non-square tubes may not work with other tubing types. Each characteristic of plastic tubing, whether square or cylindrical, made of polyethylene or polyurethane, or produced through plastic extrusion or cell casting, has advantages and disadvantages. Finding the ideal plastic tubing can take time due to the enormous number of alternatives. Contacting a reliable, knowledgeable manufacturer may help one obtain plastic tubing appropriate for specific uses.

Choosing the Correct Square Plastic Tubing Company

To make sure you have the most positive outcome when purchasing square plastic tubing from a square plastic tubing company, it is important to compare at least 5 companies using our square plastic tubing directory. Each square plastic tubing company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each square plastic tubing company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple square plastic tubing companies with the same message.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services