Medical tubing is used for various purposes, such as allowing professionals to give fluids and allowing gas to flow. Medical tubing is commonly used for ventilators and IVs, but it is also used to support access devices and as a distribution mechanism for other equipment. Read More…

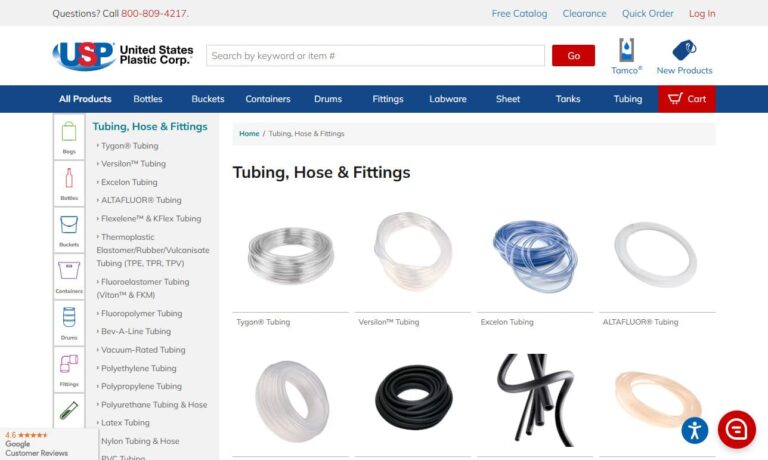

A leading manufacturer and fabricator of flexible plastic tubing and hose, we produce and stock large quantities of a wide variety of materials, including PVC, polyurethane, silicone, nylon and many more.

At Absolute Custom Extrusions, we specialize in plastic tubing, while providing custom plastic extrusions and profiles. Products include distributor tubes, hot or cold water tubes, automotive tubing, medical tubing, shipping tubes and golf club tubes.

Petro specializes in plastic tubing, offering custom extruded tubing, coiling & angle cutting. Our clear & color plastic tubing is available in Polycarbonate, Acrylic & PE-PP-Nylon.

We are a leading custom extruder of plastic shrink tubing, flexible as well as rigid tubing and profiles. Pexco offers tubing in a wide range of standard and custom colors in a multitude of material options like Polysulfone, PVC, polyurethane, nylon and more. We use state-of-the-art machinery and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001...

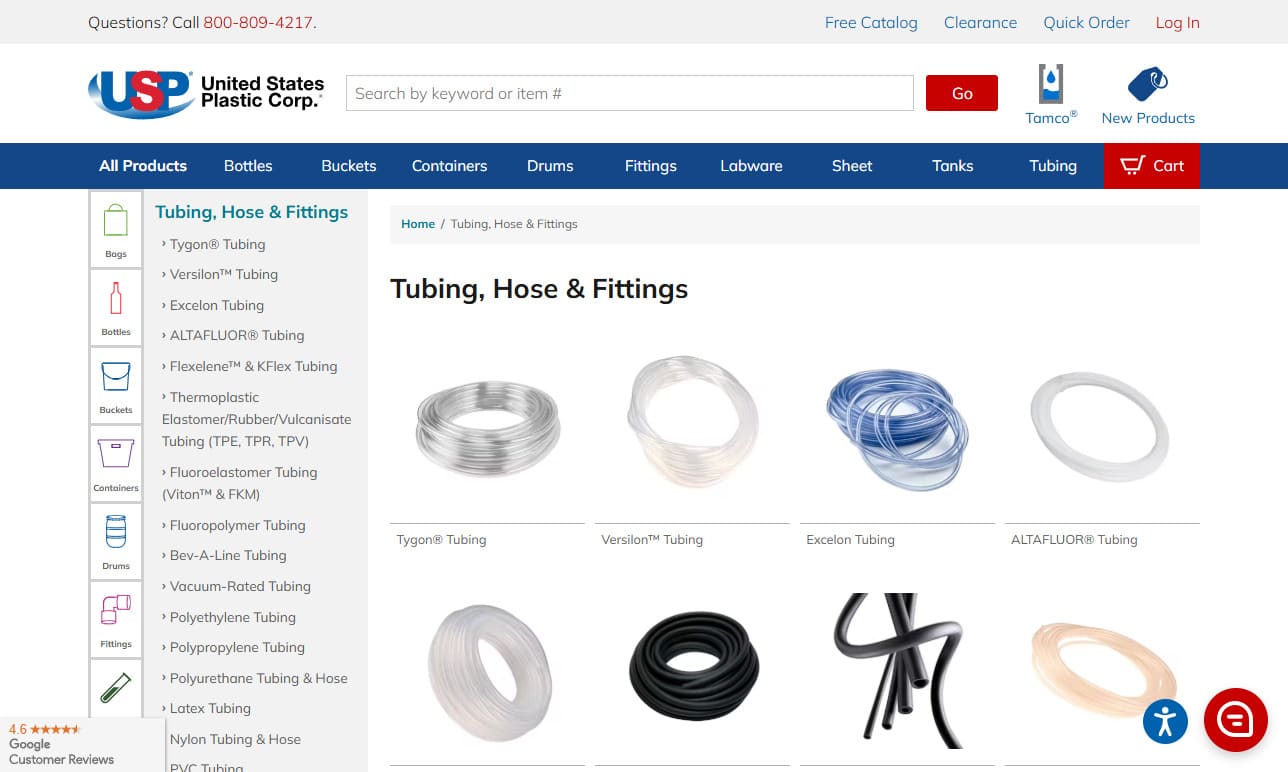

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

GSH is a manufacturer of plastic, extruded, nylon, polycarbonate and polyethylene tubing. We serve a variety of industries with our products, including automotive, consumer, electrical and marine.

When you choose Plastic Extrusion Technologies, you can rest assured that your custom plastic tubing requirements will be met with precision and excellence. We take pride in being a leader in the custom plastic extrusion industry, consistently striving to exceed your expectations and deliver the solutions you need.

If you are in search of quality plastic tubing then you have found the company that can meet your needs. We have a wide variety of stock plastic tubing items and our solutions are very reliable.

More Medical Tubing Manufacturers

What is Medical Tubing?

In the context of plastic tubing, medical tubing products are hollow, generally clear plastic channels used only in healthcare applications.

Plastic tubing is required in many areas of the healthcare industry, including hospitals, clinics, outpatient services, and many more.

Manufacturing Process of Medical Tubing

Plastics such as polyvinyl chloride (PVC), polyethylene, thermoplastic elastomers (TPE), nylon, and silicone can be used to make medical tubing. PVC, on the other hand, is the most popular, accounting for roughly 30% of the market. Extrusion and pultrusion are the two ways of making plastic tubes.

Extrusion

The extrusion process is divided into various parts. The major ingredient is polymer resin, which is supplied into a hopper located on the extruder's barrel as nurdles, pellets, granules, flakes, or powder.

The resin flows from the hopper's feed throat into a barrel with a screw that propels the resin toward the die. The resin is gently heated to a melting point as it moves down the barrel, pushed along by the screw.

Temperature, speed, force, tension, and time are all controlled by sophisticated extrusion equipment.

Pultrusion

Pultrusion, like extrusion, is a continuous-feed method for creating tubular profiles. Pultrusion, unlike extrusion, pulls reinforced fibers through a die after they have been wetted with a thermoplastic resin.

As the fibers pass through the die, they polymerize. Pultrusion is a low-maintenance, high-efficiency technology for making corrosion-resistant, low-thermal-conductivity plastic tubing.

Types of Medical Tubing

The different types of medical tubing include:

IV Tubing

IV medical tubing is thin, flexible, and made of plastic. They're used to transport medicine from a bag or bottle to a tiny needle or intravenous catheter inserted into a vein in the body.

IV tubing is useful for a variety of treatments. Furthermore, it is used to directly inject blood products, drugs, fluids, and nutrients into the human bloodstream. This tube has been manufactured in a variety of diameters and lengths.

IV tubing is necessary to connect the IV bag to the patient. Polyethylene, PVC, and polypropylene polymers are used to make these tubings. PVC tubing has also been softened with plasticizers to make it more flexible.

G-Tube

One of the most frequent types of medical tubing is the G-tube. G-tubes are extremely beneficial for patients who are unable to consume enough nutrients. As a result, individuals who require nutrient support must rely on these tubes.

A small cut in a person's abdomen is required to introduce it into their stomach. As a result, a G-tube is primarily used as a feeding tube for a gastrostomy.

J-Tube

J-tubes, which stand for jejunostomy feeding tubes, are a widespread and well-known medical device. They can also aid in delivering drugs and nutrients to the body. This tube must be put into the intestine's middle section. Furthermore, these tubes can be used in situations when the tube must be used permanently. J-tubes are very useful medical tubing; however, they are most often used when G-tubes are not an option.

In addition, these tubes are quite intricate. As a result, they cannot be changed at home without radiology. J-tubes are often lengthy or in the shape of buttons.

Vascular Catheters

Vascular catheters are used to access the human circulatory system's blood vessels to perform various therapeutic and diagnostic procedures.

However, these procedures are entirely dependent on the type of device used. For example, this type of medical tubing is employed when patients require fluids or IV medications.

They are also inserted into the arm vein, where they can remain for several weeks.

Urinary Catheters

Medical tubes like these are frequently used to drain and collect urine from the bladder. They are also useful for:

- Checking urine production

- Diagnosing lower urinary tract problems

- Introducing medicine

Low durometer polymers are recommended for exceptional flexibility. Additional options include Pebax resins, soft TPU, Isothane 5075A, and other materials.

Choosing the Proper Medical Tubing Manufacturer

To ensure you have the most beneficial outcome when purchasing medical tubing from a medical tubing manufacturer, it is important to compare several companies using our directory of medical tubing manufacturers. Each medical tubing manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the manufacturer for more information or request a quote. Review each medical tubing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple medical tubing companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services